Please note: At the time (2002), I didn't have the means to measure the acoustic output of the loudspeaker, so the frequency response characteristics of the drive unit were unknown. This meant that a lot of the design work was performed subjectively (with comparison to known references). The design detailed here worked pretty well, considering, but I don't recommend copying it wholesale as it stands - it will need to be modified for your drive unit and your enclosure. That said, I have since changed the drive unit for one that is currently available, so if you especially need a powered loudspeaker based around a 3" drive unit, details are on the modifications page.

Circuit details

The circuitry is based around an LM833 dual op-amp, and a TDA2030 power amp IC. Click the thumbnail to view the complete schematic...

As you can see, it's mostly straightforward stuff, although there are one or two interesting bits, such as the tone control and frequency shaping section, and the clipping detector.

Input buffer

This is the input section, starting with an ultrasonic filter that turns over at around 150kHz with typical source impedances - a simple (and essential) measure to stop the input op-amp picking up cellphone noise, etc. From the volume control, the non-inverting op-amp stage has a voltage gain of 20dB. The low frequency -3dB point of this stage is around 13Hz - this might seem unreasonably low for such a small speaker, but the system LF behaviour is formally set by the next stage...

High-Pass Filter

Directly after the input buffer is the high-pass filter. This is a second-order Bessel filter, chosen for its superior in-band phase response and step-response, compromising on flatness of frequency response in the passband, which is obviously pretty academic with this sort of loudspeaker. Incidentally, for a good introduction to active filters, I recommend Chapter 5 of The Art of Electronics by Horowitz and Hill.

With the values shown, it turns over at 75Hz. The output from the drive unit has fallen by about 10dB at this frequency, so there's little benefit from feeding lower frequencies into it - this will just waste energy.

Tone Control and Equalisation

Following on from the HPF stage is the tone control and equalisation section. This might look slightly strange at first, but the basic idea is to use capacitors to shape the frequency response.

The 22K resistor forms a potential divider with the 4K7 resistor (the one connected to ground). Assume that at mid-range frequencies, the 2n2 capacitor is open-circuit and the 120n capacitor is a short-circuit. The circuit therefore has an attenuation of around 15dB.

But the 4K7 and 2n2 combination bypasses the 22K resistor at high frequencies, providing treble boost. At the frequencies where the capacitor looks more like a short-circuit, the overall attenuation is only 6dB, or in other words, relative to the mid-range, there is a HF lift of around 9dB.

The 4K7 and 120n combination provide bass boost in a similar fashion. At bass frequencies, the 120n capacitor looks more like an open-circuit, meaning that the 4K7 resistor does not play a part in the potential divider. As the impedance of the next stage is 22K, the attenuation here is also 6dB, so again there's a 9dB bass lift...

The tone control is able to remove this bass boost by short-circuiting the 120n capacitor (with the control full clockwise). When the control is fully anticlockwise (bottom of diagram), the 22n capacitor is connected in series with the 120n capacitor to the bottom half of the potential divider, effectively cutting the HF response. With the control in the centre position, it doesn't really play a significant part in shaping the response of either the bass and treble boost circuits.

Just to prove all this works, here's a simulation of the complete circuit showing the gain from the input right up the output of this stage. The power amplifier is excluded as this can be assumed to have a flat frequency response. Click the image to see a larger version...

The white trace is the response with the tone control in the centre position; the green trace shows the treble-cut achieved with the tone control at minimum; and the blue plot shows the bass-cut that occurs when the tone control is set to maximum. The simulations broadly confirm the numbers discussed above, which were "worked out on the back of an envelope".

This sort of frequency response shaping used to be very popular with transistor radios and TV sets in the "good old days". Ever wondered why old Roberts and Grundig radios sounded so nice? Unfortunately, many manufacturers don't seem to bother these days...

Power Amplifier

The TDA2030 power amplifier stage comes pretty much straight from the datasheet.

The gain is 11 (21dB), but the 22uF capacitor reduces the gain to unity at DC to prevent DC offsets appearing across the voicecoil. This measure is perhaps less necessary with newer chip-amps like the LM1875, so it's not uncommon to see this component omitted. The 1n4001 diodes are 'catch' diodes to prevent the inductive load of the loudspeaker causing voltage spikes that might be greater than the supply rails - again these are much less necessary with modern chip-amps that employ measures like "SPiKe" protection - check the datasheets carefully. The amplifier is decoupled with 100n capacitors mounted next to the IC, and as the main power supply capacitors are only a few centimetres away from the IC, this is perfectly sufficient. Finally, there is a Zobel network to ensure the amplifier remains stable with the inductive load of the loudspeaker.

Clipping Detector

Finally, this is the clipping detector. I had some spare space on the circuit board, and this was an idea that I'd wanted to try for some time now...

The basic problem with many clipping detectors is that they trigger at some preset absolute threshold - which doesn't take into account the actual values of the supply rails. As power amplifiers are almost always supplied by unregulated power supplies, this is a serious shortcoming. The detector threshold would have to be set up to trigger during worst-case instances of low mains supply and maximum supply voltage sag. But under more favourable conditions, the clipping indication could be triggering several dBs below maximum output.

So this design responds to the difference between the output signal and the supply voltages. Under normal operating conditions, both transistors are conducting, and the LED inside the opto-coupler is on. This means the transistor in the opto-coupler is on, so the BC548 and red LED are both off.

Should the output get within around 2V of either supply rail, the appropriate transistor will switch off. This means the opto-coupler LED will extinguish, and then the 27K resistor will supply base current to the BC548, turning the clipping light on.

This circuit could be improved in a number of ways. For a start, there is no form of "pulse stretching", so very brief transients or HF clipping might not be seen. As there is so much bass boost in the preamp and no tweeters to burn out, I didn't worry about this here. Also, it is relatively tricky to adjust this circuit to respond to different power amplifiers - not all of them can actually get to within 2V of the supply rails under all load conditions. In addition to the resistor values, the number of 1n4148 diodes determine this threshold - adding another diode to each subtracts around 0.6V from the threshold. This is fine at the prototype stage, but a pain to adjust once you've etched the PCB!

Since building this, I've found a similar circuit on Rod Elliots site. Compared to my circuit, I think that the comparator makes it slightly more complicated - I much prefer my opto-coupler arrangement. But I think that the arrangement of the detector transistors is probably better because they can switch off faster, hence it will respond to HF clipping more effectively. Not an issue for this application, but I will be investigating this in the future...

Want to build one?

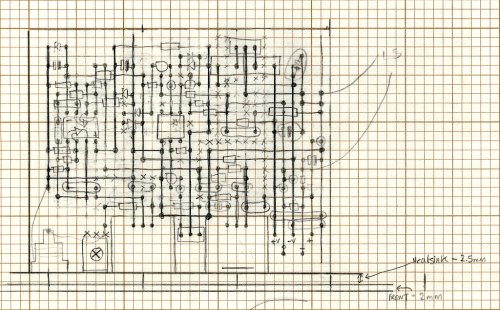

Following a recent request from an interested constructor, I've scanned the diagram of the Veroboard layout that I devised while building the unit. The original pencil drawing had plenty of corrections as it evolved, so it isn't the clearest diagram in the world. There are no component markings - at the time, the circuit was "in my head"; labels would have just cluttered the diagram.

Also note there are small differences between this drawing and the actual unit - this is because of possibilities which become apparent at the construction stage, though obviously there's no point modifying the drawing at that stage because this was a one-off. The track cuts are signified in two ways - most obviously the "X", but also (indirectly) the lines drawn I've drawn to show continuous tracks. Take care, because I've just spotted a missing X!

There are circuit differences too. The layout shows two diodes per transistor for the clipping detector, but on testing, I decided to reduce this to just one per side. Also, I planned to have Zener diodes to regulate the supply to the op-amp, but these weren't needed in practice. Stick with the LM833 - others might produce pops and bangs when switched on/off (certainly a TL082 did, but that's not unusual IME). And be realistic - the NE5532 or OPA2134 would be complete overkill! Obviously, the clipping detector is optional.

I'd strongly recommend you follow my approach: build your speaker into a box, and experiment with solderless prototype board until you're happy with the sound. For example, a larger drive unit might benefit from a lower frequency HPF (increase the 82n capacitors). The deliberate dip in the midrange designed to suit my small driver might cause better drivers to lack "presence", in which case, alter the component values around the tone control. Having said that, this EQ should make most non-hi-fi speakers sound bearable, or even "nice"!

Regarding mechanical issues, the aluminium bar was used principally to avoid visible fixings on the front panel - the TDA2030 bolts to the bar, and the bar is held in contact with the case by the two potentiometer bushes. Feel free to omit the bar if you don't mind the screwhead on the front panel (plus another from the right-angle bracket that supports the other side of the board), although note that this makes servicing more difficult. Don't forget to insulate the tab of the IC from the case, as it's connected to the negative supply rail. If the front panel is wood, you must arrange for some form of heat sink for the IC - although it can be tested briefly with no heat sink, it must be cooled effectively in use. Should it overheat and fail internally, it will probably destroy the loudspeaker!

If you're tempted to make changes to the layout, don't! Especially don't alter the earthing or power supply arrangements! Doing so will lead to an increase in distortion or maybe even cause the amplifier to "hum". Finally, I'd recommend that you build this very carefully, working your way logically through the circuit as you go. Don't just blindly follow the layout - like me, you'll need to have the circuit in your head (being forced to work out the component values will help here). While this circuit is not complicated, and it doesn't look particularly cramped, there was a lot of work to fit the circuit onto the board. Moving things just one hole might stop other things fitting!

Despite the above, it's not too difficult really. If anyone succeeds in making this work, please send me details of your version, and a picture or two. Good luck!

You can click the image to see a larger version...

Conclusion (2002)

This turned out really well given the original low cost of the drive unit. All of the components were recycled or inherited, meaning this was a genuinely zero-cost project. We use this in conjunction with my Sony SRF-M48RDS walkman as a bedside radio, where it is very pleasant to listen to, especially quietly late at night. But it can play loudly when required, and I've used it to listen to the radio while doing noisy DIY jobs. Given the help of corner placement, it produces surprising amounts of clean, good quality bass for its size.

The case is a very effective heat sink - it doesn't warm up even after prolonged use at high levels. It powers up and down cleanly, and doesn't hum or hiss. So, a simple, nice sounding, user-friendly product!